The cooling towers separate heat from the process and dismiss it to the atmosphere via the evaporation process. In the typical usage, water is pumped via the process or process machinery where it withdraws heat. The warm water is pumped-up outside to the cool tower where it is apportioned over a serial of plastic sheets (fill) in the internals of the cooling tower. The electrically powered fans move the air via the tower and ground a small part of water to vaporize that cools the remained water left of the cooling tower. This procedure operates more expeditiously and gives much cooler water temperatures in comparison with simple fan-cooled air spirals.

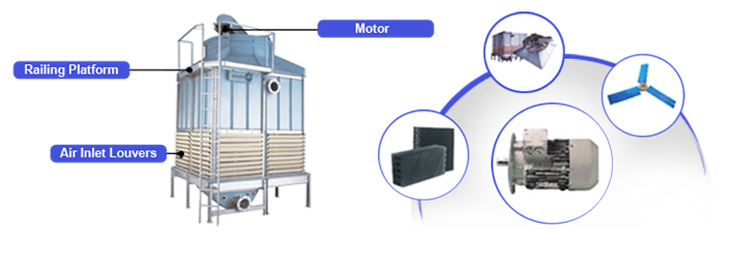

Advance Cooling Towers Pvt. Ltd provides internal supports and cooling towers with rust resistant fiberglass exteriors, which are lightweight and need low maintenance. Configured for years of reliable service, Our DM Series Cooling Towers, RM Series Cooling Towers and TM Series Cooling Towers can defy the rough conditions of industrial situations more better in comparison with traditional galvanized steel cooling towers and are the best picks for industrial cooling towers.

We, Advance Cooling Towers offer speedy, free inspections, which are concise and well-timed too. We pay attention to the cooling tower problems that can reason in future disruptions.

Our well trained crew of professionals, our wide knowledge of cooling tower systems, and our accession to all leading parts suppliers ensures that all needful repairs and advances are done rightly and the wholeness of the system is reliably reconstructed.

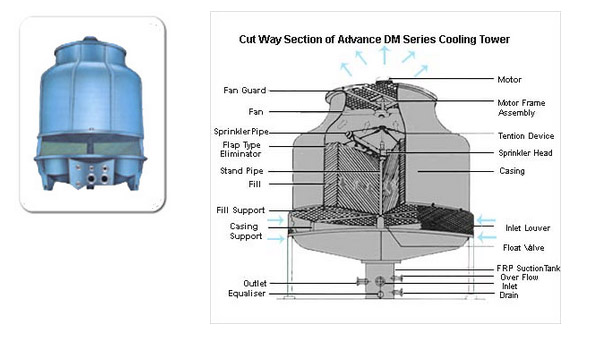

DM Series

18 Models from 5 TR to 600 TR in each Cell

RM Series

Modularly structured towers to ensure scalability in tune with changing requirements. Available in choice of 24 models with multi cells to suits the most difficult site dimensions.

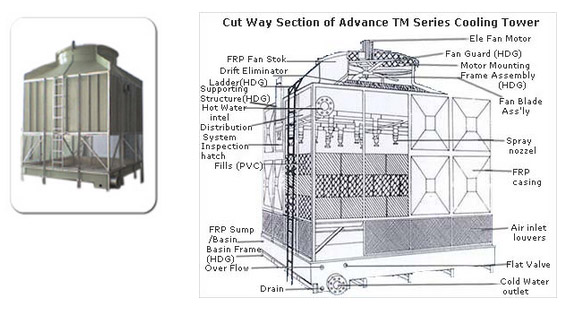

TM Series

24 Models from 30 TR to 3000 TR in each Cell